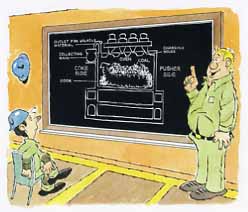

A coke oven is a tall (20-feet high), narrow (1and1/2-feet wide), deep (up to 50 feet front-to-back) metal box lined with heat-resistant brick. Fifty or more individual ovens are usually placed side-by-side to make a coke oven battery.

Each oven is heated to a temperature over 2000°F by gas fires that burn in flues within the dividing walls. When coal is baked inside the oven, the moisture and volatile chemicals are driven off, leaving a porous material that is almost pure carbon. This is coke.

A single oven will hold between 15 and 35 tons of coal, depending on its size. The coal spends about 17 hours inside the hot oven as it is transformed into a load of coke.

J&L's coke batteries are located at Aliquippa, Pittsburgh, Youngstown and East Chicago. Most are conventional ovens. However, our new A-5 coke battery is one of the most advanced units in use today (above).

Unlike conventional ovens, the A-5 ovens do not have charging holes" in their tops. Instead, coal is fed into the A-5 ovens via a pipeline system. This method reduces the leakage of gas and particulates that can pollute the air.

Coal for the A-5 is preheated to 500°F before it's fed into the ovens. This step lowers coking time to only 12 hours.

How is coke removed from a coke oven? That's a good question... and the answer is simple: large doors at the front and back of the oven are removed and the hot coke is pushed by a huge pushing machine into a railway car. Then, the car moves under a special tower where sprays of water cool the coke.

During the coking cycle, gases and volatile substances are baked out of the coal.

We capture the gas and burn some of it in the flues of the coke ovens. The rest is used as a fuel for other steel making operations. The production of this valuable fuel is important to the entire steel plant and, for example, amounts to 80 million cubic feet each day at both Aliquippa and Pittsburgh.

We collect the oils, tars and other volatiles

and send them to a by-product recovery plant, a miniature refinery

that turns them into many valuable chemicals.