Coke making, iron making and steelmaking operations all produce large volumes of waste materials that can cause air and water pollution if they enter our environment. J&L is working hard to control pollution. We've pledged that new facilities will be designed to meet or exceed reasonable government standards for air and water quality, and that existing facilities will be brought into compliance as quickly as technology and economics permit.

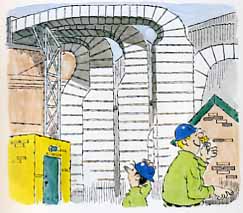

To date, we've spent more than $325 million to install pollution control equipment at different works and plants like the smoke abatement facility at our Warren Plant (above right). We plan to spend another $375 million in the near future to buy more equipment and to modify existing facilities to improve air and water quality.

Operating and maintaining this equipment costs money too: right now, we spend about $45 million every year and we will spend more in the future as new pollution control gear is put in place.

Our major works offer the greatest challenges; we're proud of our recent accomplishments. For example:

The A-5 coke battery at Aliquippa uses an advanced pipeline charging system that eliminates charging emissions. The battery also has a large hood that collects pollutants released when hot coke is pushed out of each oven.

The water recycling systems at Cleveland (above) and Indiana Harbor have been cited for their excellence by the Federal Environmental Protection Agency. In 1976, the Cleveland Works received the Region V Environmental Quality Award from the U.S. EPA.

J&L is constructing an electric furnace

complex for the Pittsburgh Works that will replace the six existing

open hearth furnaces and four existing blast furnaces. The new

facility will be equipped with the most modern pollution abatement

technology. The planned completion date is May, 1979.