A junior beam is a miniature structural I beam that is widely used in mobile homes and other light construction. It is a hot rolled product made by reducing a heated steel billet on our 14-inch rolling mill at Aliquippa (above). We also manufacture junior channels and a line of rolled steel angles and tees.

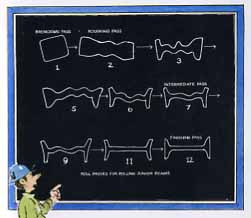

Junior beams and structurals are really special kinds of hot rolled bar products. The rolling mill's hardened steel rolls are shaped to squeeze the hot steel into the structural's cross section. You might find it hard to believe that rolling can transform a square section billet into an I section beam. To show you how it's done, we've diagrammed the different roll passes in the illustration (above). Each pass is a trip between one pair of rolls.

As you can see, the process has four distinct stages:

1. Breakdown passes-The first groups of rolls squeeze the billet slightly smaller, then give its cross section a strange four-eared shape that doesn't look much like an I. Essentially, these early passes are moving steel around to where it will be needed farther down the line.

2. Roughing passes-Now, the beam's true cross section begins to take shape, although the arms of the I are still too bulbous and they are tilted at odd angles.

3. Intermediate passes-These are the detail-forming passes that establish the thicknesses of the beam's flanges and webs. Simply stated, the intermediate roll pairs move steel into all of the right places and give the developing beam the proper I shape.

4. Finishing pass-The last step is to adjust the length of the flanges and push them into the correct position.

Other structural shapes are made by different

combinations of passes, although the concept of breakdown! roughing/intermediate/finishing

passes applies to all.