J&L invented the cold finishing process nearly 120 years ago. It happened when an engineer at Jones, Lauth & Company watched a worker drop a pair of tongs into a rolling mill. All that emerged from between the rolls was a mangled mass of iron, or so it seemed at first glance. Closer inspection revealed that squeezing the cold metal between rolls had both increased its strength and given it a good surface finish.

Cold rolling of bar products is still used today to cold finish wide, rectangular pieces of steel called flats. However, virtually all other cold finished bar products are made by drawing hot rolled bars through hardened steel dies.

A typical die has a slightly smaller cross-section than the hot rolled bar it finishes. Thus, the cold finished bar that emerges from the die is slightly smaller and slightly longer than the hot rolled bar that entered the die. And, it is stronger, tougher, harder and has a far superior surface finish.

J&L cold finishes bars of many different shapes and sizes at our facilities at Pittsburgh; Hammond, Indiana; Willimantic, Connecticut and Youngstown Ohio. As you might expect, substantial force is necessary to pull a hot rolled bar through a die. The primary tool of cold finishing is the motor-driven draw bench.

Most of the cold finished bar we make is used as a raw material to manufacture machined parts, everything from motor shafts to ball bearings to engine camshafts to water valves. For a number of reasons, cold finished bars are easier to machine than hot rolled bars.

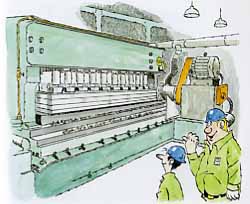

Cold rolled milled-edge flats are exclusive

J&L cold finished products. These are cold rolled flats that

are milled by a special machine to trim their edges square. The

illustration (above) shows this machine in action. The unique

flats are used in many different applications that require sharp,

square, precise edges.