It's been said, without much exaggeration, that the world rolls on hot rolled steel bars. These bars are the raw material for car and truck components such as axles, drive shafts, engine and transmission parts, and bearings. And, hot rolled bars are used to make tools, chains, fasteners of all types and many other familiar items.

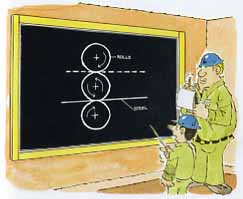

Hot rolled bars are made by squeezing red-hot billets of steel between shaped steel rolls (above). There are 10 or more pairs of rolls arranged in a series of stands. Each pair of rolls reduces the cross-section diameter of the bar. The process reshapes the hot steel much like a child shapes a block of clay into a clay rope.

Not all hot rolled bars are round. Many have square, hexagonal, rectangular or special cross-sectional shapes. It's all a matter of designing rolls that impart the shape desired by the customer.

The illustration (above), shows partially rolled bar speeding around a looping table on its way to another group of roll stands. One reason to reverse direction like this is to allow the construction of a more compact rolling mill.

Depending on its diameter, a length of bar emerging from the rolling mill can be upwards of 300 feet long. The hot rolled bar is cooled on long open tables and then cut to desired length and straightened, if necessary.

We make hot rolled bar products in two mills at Pittsburgh and one at Aliquippa. Carbon steel bars represent the bulk of our shipments, but we also roll alloy steel bars.

Because hot rolled bars find their way into

tough applications, J&L bar-makers exercise great care during

every step of manufacture. We work hard to ensure internal soundness

of the steel and freedom from serious surface defects.