Click Here to Return to Milestones

When the colonies won their independence from England, they still relied heavily on England for many of the necessities of their pioneer existence. America was an agricultural economy and the English wanted it so. They were busy importing slaves to the West Indian Islands and the Southeastern states to produce more cotton for the English mills. Most of the iron utensils, including the chains for the slaves, came from England and a small amount from Germany.

In the early 1800's, the colonies were blessed by the arrival of some of the more erudite European men attracted by the struggling republic and the wonderful men who governed it. One of these men was Detmar Basse. His full name was Detmar Fredrick Wilhelm Basse, born in Iserlohn, Province of Westphalia, Prussia on April 6, 1762. He was married to Sophia Wilhelmina Keilner in Frankfort am Main, her home town. A daughter, born in 1786, named Fredrica Wilhelmina (Zelie) - the latter a childhood pet name which she used through her entire life. She married Philip Louis Passavant, who was also from Frankfort. At that time, Frankfort was an independent city-state, although it was a part of the Grand Duchy of Hesse - birthplace of Goethe, but also the locale of the infamous Hessian troops who fought for England against the American colonists in the Revolutionary War. Some of these soldiers deserted and settled in Pennsylvania.

Detmar Basse's wife died in Paris in 1800 where he held a diplomatic post in the French Government for ten years. He had inherited a large fortune and was given the complimentary title of Court Councilor from the Elector of Hesse-Kassel for having lent him a large sum of money to free prisoners of war during the Napoleonic wars. He also gave a large sum of money to the City of Frankfort for the same purpose.

He was given the key to the city which is still in the family in Zelienople.

Basse first came to America in 1802 or 1803. He went back to Germany in 1806, having purchased a huge tract of land (10,000 acres) where Zelienople now stands. He returned again to America in September, 1807, accompanied by his daughter and her husband. He erected a pretentious three story wooden castle with towers, turrets and battlements which he named "Bassenheim". It was destroyed by fire on July 29, 1841.

The Baron was a very well educated and brilliant man who saw the various needs of the colonists. He built a brick yard and produced good "Brig" as they were then called. He also built a flour mill, and realizing the need for iron products, and to acquaint himself with the iron industry, he is said to have visited the iron works near Connellsville in Fayette County, as well as those in the Juniata Valley where he secured a competent manager, John H. Hopkins, who later became the Episcopal Bishop of Vermont.

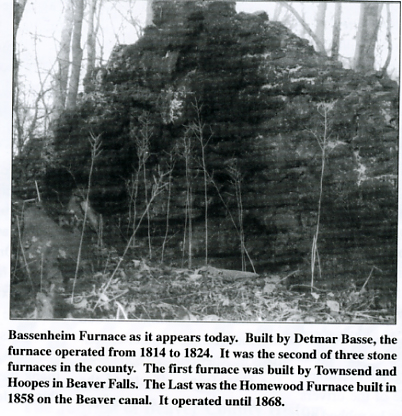

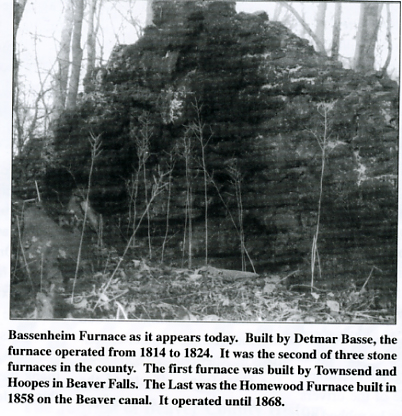

Bassenheim Furnace was built about 1813-1814, and was the second farthest west iron furnace. The furnace was constructed of sandstone, probably from the famous ironstone deposits near New Castle. It was on the bank of the Connoquenessing Creek. The ruins still stand. Power to run the bellows came from damming up the creek and installing a water wheel. Ore from the furnace was from small deposits nearby. These can also be seen by anyone interested in the local geology. The ore was blue in color and was in nodules in the shale, but some was in the form of lumps weighing as much as 50 pounds.

The fuel, or course, was charcoal from the surrounding forest and the limestone flux was hauled from a ledge a mile north of the furnace. The bellows that furnished the blast was first operated by waterpower from the creek, but when high water undermined the dam, a steam engine was used which materially increased the cost.

The iron was a very good grade of soft charcoal iron and very tough. Most of the production was for utensils, such as large kettles, stoves, and fire irons, but what was left over from a cast was cast into pigs or shot. Pig iron was often used as currency and was often traded for whiskey of local manufacture at the Ziegler Store in Harmony.

A beautiful specimen of casting from this furnace is the fireplace which was in the Passavant Homestead where Zelie, and later Miss Emma Passavant, resided.

In the year 1816, a contract was made with the War Department to furnish round shot. The War Department furnished the molds and a man to supervise the casting.

In 1818, Basse sold the furnace to Daniel Beltzhoover who worked it for five or six years more until the ore began to fail and the furnace was then abandoned. The furnace was of six tons capacity, and the iron was of very good quality - not "Hot Short" nor "Cold Short" - terms used in those days when the balance of the trace ingredients such as sulphur, phosphorus, and silicon were not known, but the result in the iron so prevalent in some of these early efforts was known, and affected the sale of iron from some furnaces.

The fact that twelve dollars per ton had to be paid to haul the pig iron to Pittsburgh also contributed to its demise.

After selling the furnace, Basse returned to Germany and died in Mannheim, Baden, Germany, on the 19th of June, 1836, and was buried there.

Basse first took as a partner a Major William Luterel Rogers, and the firm became D. Basse and Rogers. This was on June 18th, 1818. That same year he sold the furnace to Daniel Belzhoover, William Robinson, Jr., and John McNickle of Pittsburgh, who operated it as noted above.

Bassenheim Furnace and others in Western Pennsylvania were the start of the steel industry in the United States. From small acorns mighty oaks grow. Who, at that time, would have imagined the growth of a mighty industry from a lot of small backyard furnaces.

The iron from Bassenheim could be forged and made into what we now know as malleable iron and which has been mostly replaced by various steel alloys. The malleable iron has a texture similar to wood and is very tough.

This characteristic was used by another Zelienople industry - the American Flexible Bolt Company - who made bolts to hold the boilers together on the old steam locomotives on the railroads. The boilers are like a saddle over the firebox and the bolts continually failed until Mr. Leo Finnegan started to make them of a special charcoal malleable iron similar to that from the Bassenheim Furnace. Furthermore, he drilled holes through the length of the bolt, so if it started to fail, iron or steam would show. The operation was later moved to the Pittsburgh area.

Zelienople has many "firsts" - the foregoing are but two of many. Quite a collection for such a small town. The brains and drive of Detmar Basse seem to have lived on with the managing ability of Philipp Passavant, who took over Basse's holdings when his fatherin-law returned to Germany in May of 1819.