Click Here to Return to Milestones

This piece of industrial history about "Kobuta" appeared in an ARCO Chemical publication in 1981. Beginning in the war years, Kobuta is an important part of Beaver County history.

The Beaver Valley Plant of Atlantic Richfield had its beginnings in the early years of World War II. The invasion of southeast Asia by Japanese troops resulted in the loss of our major source of rubber, and even before the United States was forced to enter the war, the federal government had initiated plans for development of a synthetic rubber industry.

With its strong background in construction of chemical plants for processing the by-products of the coke industry Koppers Company of Pittsburgh was selected by the Defense Plant Corporation, a wartime agency of the United States government, to build a facility on the Ohio River to produce styrene and butadiene. These substances werc the essential ingredients for making Buna S rubber, the best type of synthetic rubber known at that time.

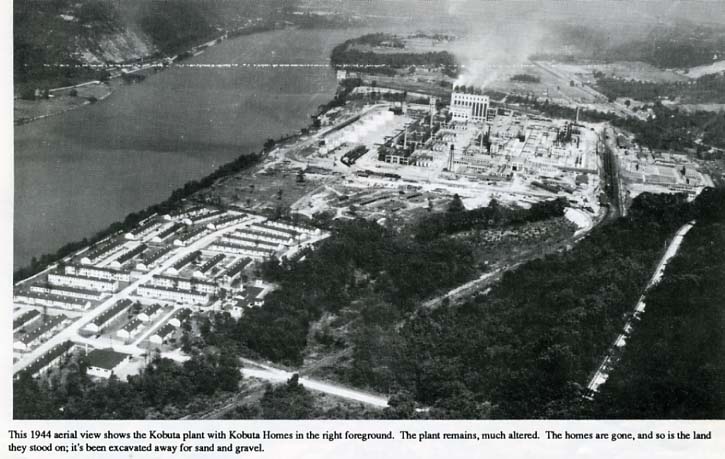

The pressures of wartime resulted in the completion of the new plant in an incredibly short time. Changes in design and capacity were made even while the plant was being built. It was only a year and a day after excavation started on the boiler house that the first boiler was fired up and started producing steam. Both the butadiene and styrene plants were shipping out tank cars of their products in less than a year after their respective groundbreakings. From the beginning of excavation on June 22, 1942, to the date when the plant was in full operation, December 17, 1943, only eighteen months had passed.

At a dedication ceremony on the date of completion, the National Rubber Director, Colonel Bradley Dewey, described the plant construction as "a miracle job" and "one of the outstanding jobs in the entire program". He also commented, prophetically, "we anticipate that this will be one of those plants that will survive the war."

The new plant was called "Kobuta", for Koppers and butadiene. In all, more than twenty thousand men and women helped build Kobuta, with as many as 7375 employed atone time (in July, 1943). More than 5000 rail cars brought in over 200,000 tons of material and supplies to complete the plant. Barracks and trailers were supplied to house thousands of workers, and a three hundred unit Defense Housing Project, Kobuta Homes, was built adjacent to the plant.

In less than two years, the plant was totally shut down. The demand for rubber had dwindled. Tbe war had been won, and Kobuta, unquestionably, had helped win it. In 1946, The Reconstruction Finance Corporation, owner of Kobuta, sold it to Koppers Company for one dollar.

It was a good investment. Styrene could be used to make polystyrene plastic, and the future for plastics looked very good. From a very modest beginning, Kobuta started producing polystyrene in late 1946. As the market grew, so did the plant output. In the middle fifties, the company entered the polyethylene and latex fields, and introduced Dylite Expandable Polystyrene. A few years later, polyethylene film was added to the product line, and Koppers introduced high-density polyethylene to the United States market.

In 1965, the Sinclair Oil Company purchased from Koppers a one-half interest in the Kobuta plant and the other manufacturing units of Koppers' Plastics Division. This marriage combined a source of the raw materials needed to make polystyrene with the equally necessary production facilities, and solved problems for each of the partners.

Sinclair's history dated back to 1916, when it was founded by the colorful petroleum pioneer, Harry F. Sinclair. The company's trademark showed a dinosaur, alluding to a theory, once popular with geologists but now refuted, that just as coal is the remains of pre-historic vegetable matter, our petroleum deposits were formed from animal tissue.

The merger brought about the first major changes in the public's perception of Kobuta. The company became known as Sinclair-Koppers and the trademark was modified to a jaunty "SK", surrounded by Koppers' familiar octagon. The plant was still managed by Koppers, however, so except for the new letterhead, Kobuta employees saw little difference after the merger.

The purchase of the bulk of the assets of Sinclair Oil by Atlantic Richfield in 1970 caused much excitement but still little change at Kobuta. It wasn't until 1974 that the plant began to feel ARCO's corporate muscles begin to move, and then the changes came quickly. First, Atlantic Richfield announced plans to purchase Koppers' share of SinclairKoppers, Inc., over the next few years. Management of SK was assumed by ARCO soon after, and company headquarters were moved to Philadelphia. Again, the plant's identity changed, but this time more drastically: the venerable name, "Kobuta", was eliminated in favor of one that was soon to be more appropriate. The new sign on Frankfort Road read, "Beaver Valley Plant, ARCO Polymers, Incorporated." ARCO Polymers was created as a wholly owned subsidiary of ARCO Chemical, a division of the corporate giant that was Atlantic Richfield.

Another change for the Beaver Valley Plant occurred following a reorganization of ARCO Chemical. The ARCO subsidiary, "ARCO Polymers", was fully integrated into ARCO Chemical and the word "polymers", which was so difficult for neighbors in Beaver County to spell, is now used only in a technical sense in the Beaver Valley Plant.

Today, the Beaver Valley Plant is a leader in production of resin for polystyrene foam (Dylite), while the new heat resistant plastics, Dylark and Dytherm, show tremendous potential for growth in the automotive and other important markets.